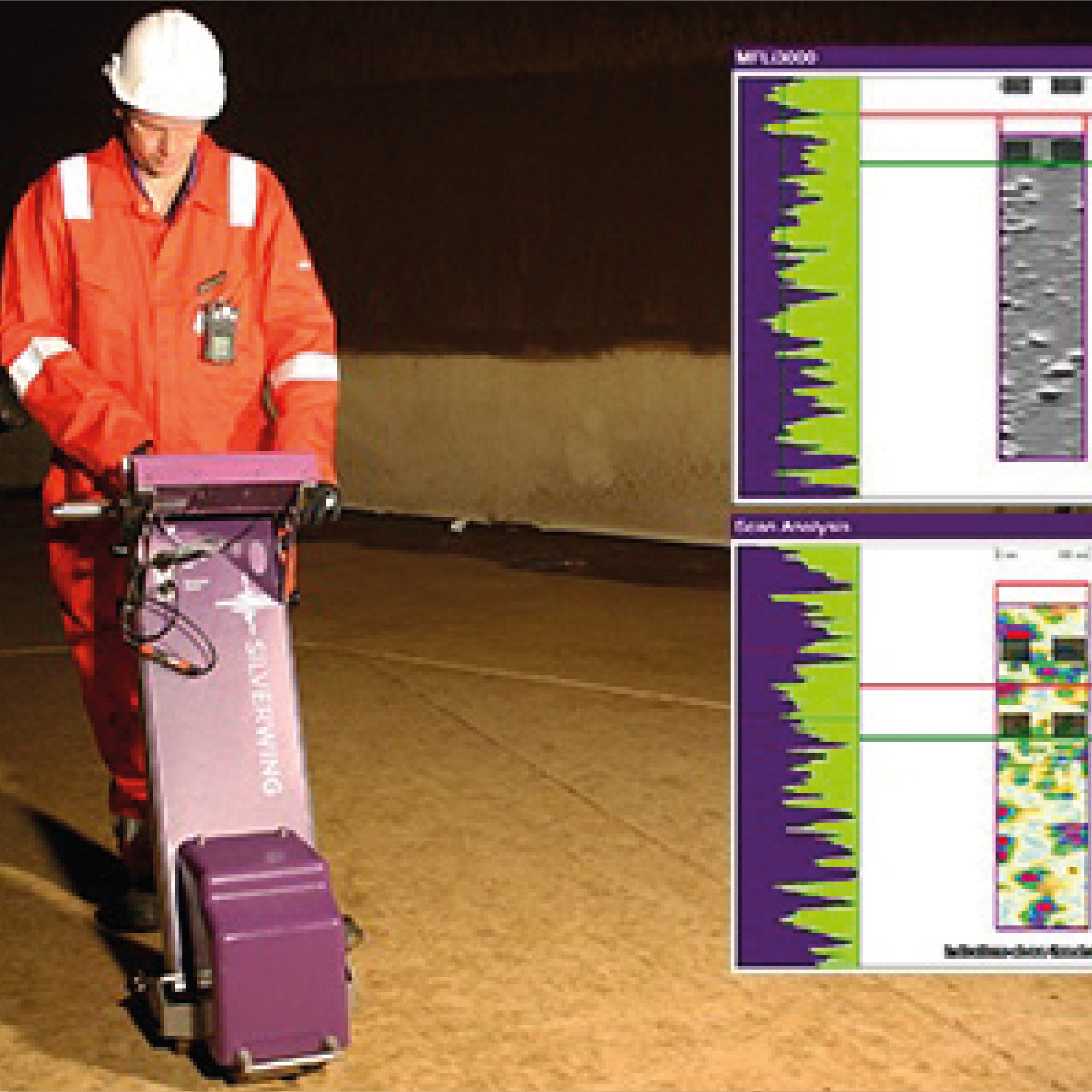

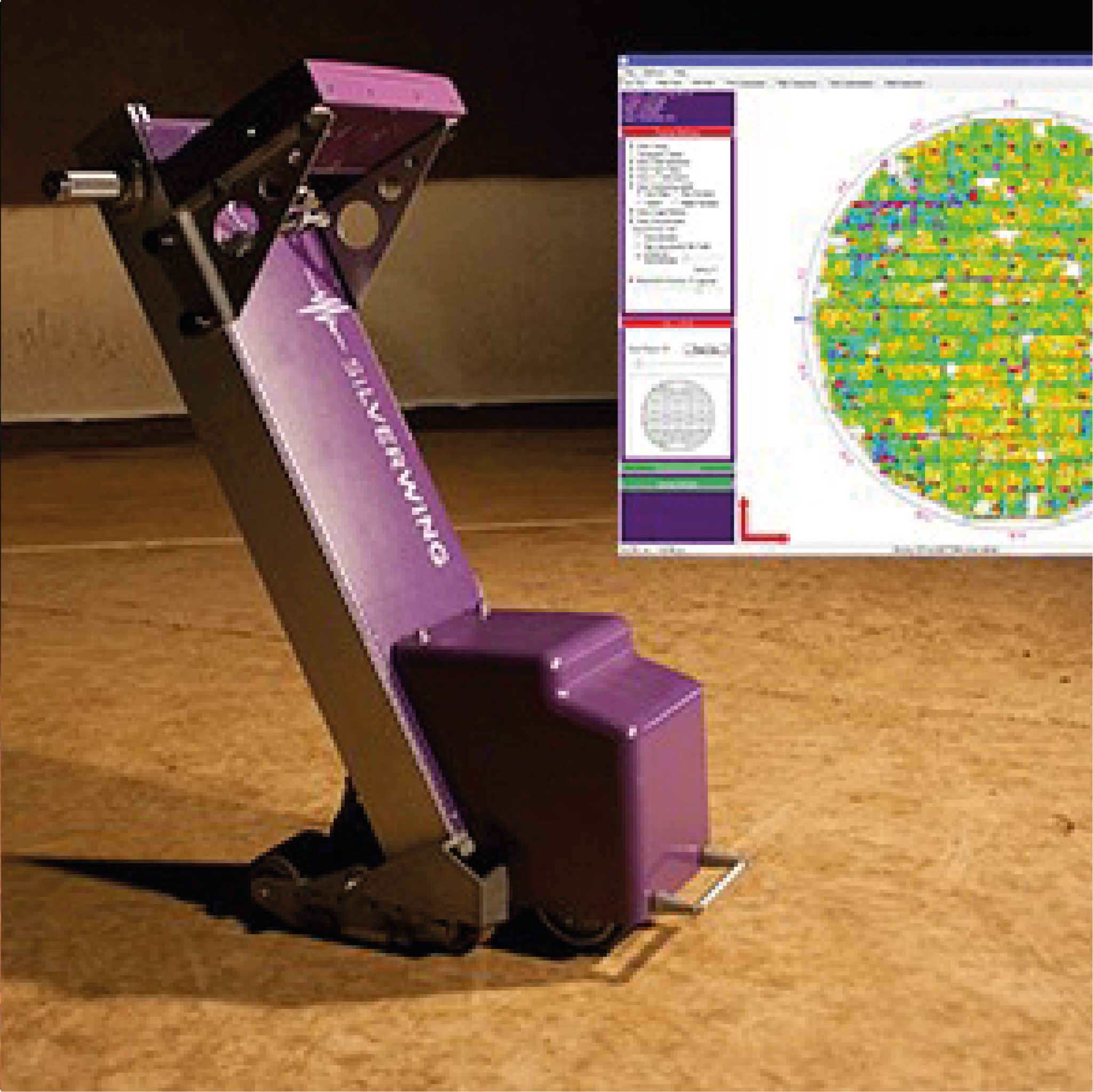

Magnetic Flux Leakage (MFL) is a high-speed, non-destructive inspection technique used to detect and size corrosion, pitting, and material loss in ferromagnetic materials such as tank floors, pipelines, and storage vessels.

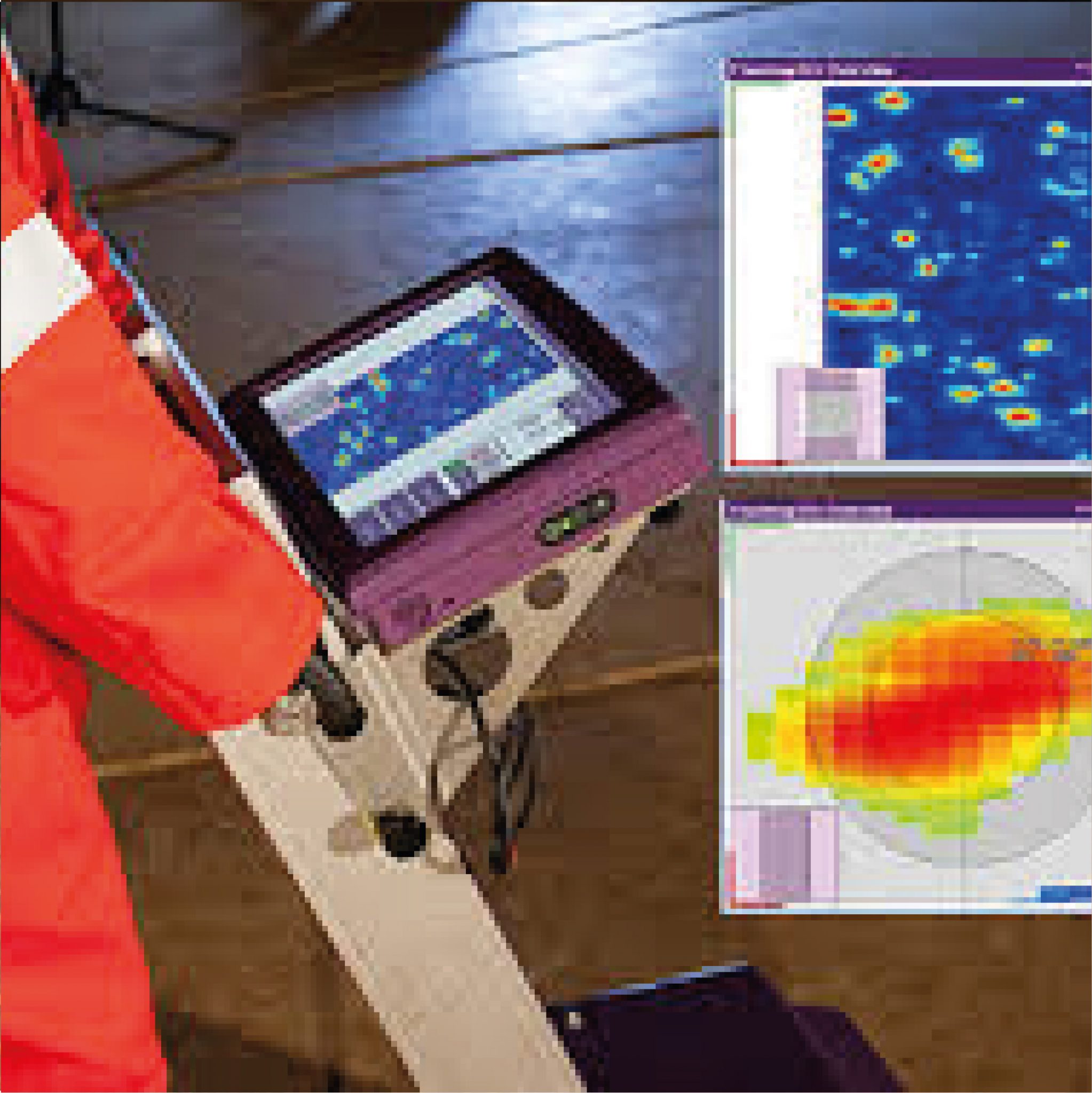

The method uses magnetizing units and Hall Effect sensors to detect flux leakage fields created by material degradation. When corrosion or thinning is present, the magnetic field is disrupted, and the change is captured by the sensor array.

Advanced systems can also discriminate between top-side and bottom-side corrosion using air-gap reluctance principles and provide real-time C-scan imaging without requiring coating removal.

Benefits of MFL:

- Fast, wide-area scanning ideal for large surfaces like tank floors

- Detects localized corrosion and material loss as small as 2 mm in diameter

- Enables top/bottom corrosion identification through signal discrimination

- Scans through coatings without the need for removal, reducing prep time

- High-resolution sensor arrays enhance defect sensitivity and orientation accuracy

- Produces C-scan corrosion maps for precise visual interpretation and documentation

- Reduces the amount of manual UT prove-up required

- Supports better Risk-Based Inspection (RBI) decision-making

- Minimizes downtime and improves inspection planning efficiency

Compatible with digital reporting systems and plant integrity databases