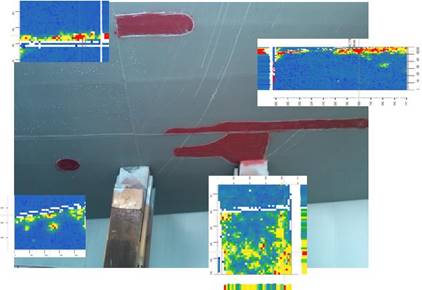

Automated Corrosion Mapping is an advanced ultrasonic technique used for rapid, high-resolution scanning of wall thickness over large surface areas of vessels, piping, and tanks, often while the equipment remains in operation. It employs robotic scanners to gather precise thickness data and generate detailed C-scan images of the inspected surface.

Color-coded imaging helps visualize areas of concern:

- Blue typically represents nominal wall thickness

- Orange and red indicate significant wall thinning or corrosion

The inspection data can be integrated into engineering drawings or digital plant models to pinpoint the location and severity of damage, enabling more targeted maintenance and integrity planning.

Benefits of Automated Corrosion Mapping:

- Inspects up to 20–30 m² per day

- Produces high-resolution C-scan images that clearly highlight wall loss

- Operates while equipment is in service, reducing downtime

- Accurate mapping of corrosion, pitting, erosion, and disbonding

- Enables overlay scans on vessels with weld overlays to assess bond quality

- Supports data-driven decisions in Risk-Based Inspection (RBI) programs

Applications:

- Storage tanks and pressure vessels

- Process piping

- Weld overlay monitoring

- CUI (Corrosion Under Insulation) evaluation

- Critical components in petrochemical, power, and offshore industries